In the cake-making business, efficient operations are not just beneficial, they are game changers. They can significantly reduce costs, increase productivity, and improve the overall quality of your products. We’ve previously explored time management techniques, and now, it's time to talk about equipment, a key player in achieving these efficient operations.

Choosing the right equipment needed to start a cake business is not just about efficiency but professionalism. For many cake makers, using high-quality cake baking tools and equipment is a mark of their commitment to excellence. In this piece, we will explore how the right equipment cannot only streamline your operations but also elevate your business's professional image.

Let’s begin with the basics.

Essential equipment for small cake-making businesses

In short, these are your go-to tools and appliances. Regardless of the type of baked goods you make, you definitely need these things. So, here they are.

Mixing equipment

1. Stand mixers

Simply put, a stand mixer is an irreplaceable appliance in your cake-making routine. It is suitable for a wide range of bakery tasks, from kneading dough to whipping cream. They are genuinely easy to use and usually come with various attachment options for different recipes. However, there are several considerations when choosing one, namely mixer capacity, speed settings, and durability.

2. Spiral mixers

Next up, a spiral mixer is an ideal choice for handling large batches of dough. Thus, you can opt for this one as it allows you to mix dense dough while being gentle on the structure efficiently. But, the same as with the previous one, consider its size, power requirements, and any special maintenance needs.

3. Planetary mixers

The last on the list is a planetary mixer. As the name suggests, it features a rotating mixing bowl and multiple attachments for various baking tasks. Planetary mixers are quite versatile in handling different mixing tasks, including whipping, blending, and kneading. When choosing this type of mixer, consider the main bowl capacity, attachment compatibility, and motor power.

Baking equipment

1. Commercial ovens

Being essential for baking a wide range of products, commercial ovens come in various types, such as deck ovens, convection ovens, and rotary ovens. Same as mixers, needless to say, they are irreplaceable. The advantages are plain and simple, too. With a properly chosen oven, you can get an even heat distribution, precise temperature control, and efficient baking performance.

However, when choosing the best oven for home baking business, there are several considerations to keep an eye on. For instance, the first and foremost is size, which must be suitable for your needs but also capable enough to be suitable for peak times when you get lots of orders. Additionally, consider the fuel type it uses (electric, gas, or convection) so that it harmonises with other cake baking equipment in your house.

2. Proofing cabinets

These are optional, and you should consider buying them if you get enough orders to justify the purchase. Proofing cabinets are used to create optimal conditions for dough fermentation, regulate temperature and humidity levels.

There are several benefits they provide. For instance, with proofing cabinets, you get consistent proofing results, accelerated fermentation, and space-saving design. However, be mindful when choosing as they occupy a lot of space. Thus, approximate some numbers and choose a suitable size, neither too big nor too small. Additionally, if you work with peculiar bakes, consider how many temperature control options cabinets offer and how energy efficient they are.

3. Baking sheets and pans

Essential for shaping and baking various bakery items, baking sheets and pans come in different sizes and materials. In fact, there are so many to choose from that it can become almost irritating to choose…

In spite, they facilitate uniform baking, allowing you to release baked goods from the oven quickly. However, choice is the most challenging aspect. Firstly, always look to see if they’re compatible with oven racks. Additionally, consider the material they’re made of, as metals like aluminum or stainless steel have different qualities.

Refrigeration equipment

1. Walk-in refrigerators

First, note that they’re suitable if you have a dedicated space. For instance, you may run a small bakery or, at least have a decent amount of space in your home-based bakery. Walk-in refrigerators are large-capacity units for storing perishable ingredients, dough, and finished products.

Needless to mention, they provide tons of storage space. Moreover, they’re good at maintaining temperature consistency and in inventory organisation. Downsides are obvious, too, however. First and foremost, their size makes them very demanding. Secondly, they’re not really accessible and are usually custom-made, which skyrockets their price. Still, it is a solid option to consider if you have enough funds and space.

2. Display refrigerators

Again, display refrigerators are a must once you have a dedicated bakery location. They showcase baked goods, desserts, and other treats while keeping them fresh and cool.

In any bakery or coffee shop, they’re an eye magnet for guests, which can greatly boost your profits. Apart from an attractive presentation and visibility for customers, they usually have decent temperature control, too.

Several things to consider when choosing a display refrigerator. For instance, size matters, as you need to plan where you will place it thoroughly. Additionally, consider display layout and energy efficiency, as they can be quite demanding.

3. Undercounter refrigerators

Now, to the essential. Undercounter refrigerators are compact units designed to fit under countertops, which are ideal for storing frequently accessed ingredients or prepared items. For the most part, they share a space-saving design, providing convenient access and temperature consistency.

When choosing one, consider sizing, as it should be compatible with available space. Additionally, think of the capacity it can store so that all ingredients aren’t clutched. Lastly, the temperature range it offers is also a valid point you should consider.

Dough handling equipment

1. Dough dividers

When you start baking in batches, you’ll need dough dividers, which are a must in most bakeries. These machines are designed to portion large quantities of dough into uniform, smaller pieces, facilitating consistent product sizing and shaping.

With their help, you can significantly save time as well as uniform product results. However, when choosing one, consider its capacity, adjustable portion sizes, and how easy it is to clean.

2. Dough sheeters

These sheeters are equipment used to roll out the dough into thin and uniform sheets, essential for making pastries, croissants, and other baked goods. Same as with dividers, dough sheeters provide consistent dough thickness, saving you a lot of time and labour.

3. Dough rounders

The last of the three dough rounders are machines designed to shape dough portions into round balls. They are ideal for preparing bread rolls, flat bases for cakes, and other rounded bakery items.

As with others, dough rounders can help you uniform dough balls to save time and reach consistency.

Looking to establish a cake-making business? Do it with CakerHQ! Sign up

Factors to consider when selecting bakery equipment

Selecting equipment for cake baking shouldn’t be impulsive or blind. On the contrary, you should be looking to invest in equipment that will work for years without issues. Hence, to choose reliable equipment, several factors must be considered.

A. Production capacity

It's essential to track the raw number of goods you’re making daily/weekly/monthly. When assessing the production capacity of bakery equipment, it's crucial to consider the specific types and quantities of bakery products you intend to produce.

To make it even more insightful, factor:

- The size of your customer base;

- The demand for different types of baked goods;

- Any seasonal variations in sales.

With raw numbers, you can more easily understand your production requirements. This, in turn, will help you ensure that the equipment you select can meet demand without overworking or underutilising resources.

One more thing before we move on. In addition to calculating the capacity, consider peak production times and fluctuations in demand throughout the day or week. The equipment you choose should be able to handle increased production during busy periods without compromising quality or efficiency.

B. Space requirements

Another critical point is the space you currently have. Understanding it can help you determine the size and layout of equipment that can be accommodated effectively. Hence, list all the equipment you plan to purchase and start measuring.

For instance, measure the dimensions of your bakery space, including floor space, ceiling height, and any potential obstacles or restrictions.

In smaller bakery setups, prioritise compact and space-saving equipment designs to maximise efficiency without sacrificing functionality. Consider equipment with modular or stackable features that can be customised to fit your space constraints. Additionally, equipment accessibility for cleaning and maintenance should be considered.

C. Budget considerations

Planning and buying are fun and games, but a sober approach to money also matters. Professional equipment needed for cake business is quite pricey, so budgeting is another crucial aspect.

In this matter, consider upfront costs and long-term expenses when evaluating equipment options. In addition to the base purchase price, factor in ongoing expenses such as maintenance, repairs, and energy consumption over the lifespan of the equipment.

When you’re done with the list of tools and equipment needed, it’s still early to buy everything right away. Now comes the research time!

Research and compare prices from different suppliers to identify cost-effective options that meet your quality and performance requirements. Additionally, explore financing options or leasing agreements to spread out the cost of equipment purchases and manage cash flow effectively.

D. Energy efficiency

Choosing bakery equipment with high energy efficiency ratings can help reduce operating costs and minimise environmental impact. Choose equipment for cake business with energy-saving features such as insulated chambers, programmable settings, and efficient heating elements. These features can help optimise energy usage and reduce utility expenses over time.

Consider the energy requirements of different types of bakery equipment and prioritize models with lower energy consumption without compromising performance or quality. Energy-efficient equipment not only saves money on utility bills but also demonstrates your commitment to sustainability and environmental responsibility, which you can turn into a valuable selling point for customers.

E. Durability and maintenance

When choosing tools and equipment, prioritise things constructed from durable materials capable of withstanding the rigors of daily use in a bakery environment. Look for equipment made from high-quality stainless steel or other robust materials. They should be resistant to corrosion, wear, and tear.

After all, durability is essential for longevity and minimising the need for frequent repairs or replacements. Furthermore, choose equipment with smooth surfaces, removable parts, and accessible components to facilitate thorough cleaning and sanitation practises.

F. Adaptability to future expansion

When selecting equipment, anticipate potential growth opportunities and changes in your bakery's operations to ensure scalability and flexibility. In layman’s terms, always think forward, as you never know when you will need to expand your operations.

Therefore, choose equipment that can adapt to evolving production needs and accommodate increased demand as your business expands. Look for modular or versatile equipment designs that can be easily upgraded or integrated with additional units to meet growing production requirements.

Moreover, along with the growth, you may want to expand your offering. Therefore, make sure to account for this reason when purchasing new equipment. It should be adaptable to handle a variety of bakery products or production processes.

Need to expand your business? CakerHQ is the right choice. Become a professional

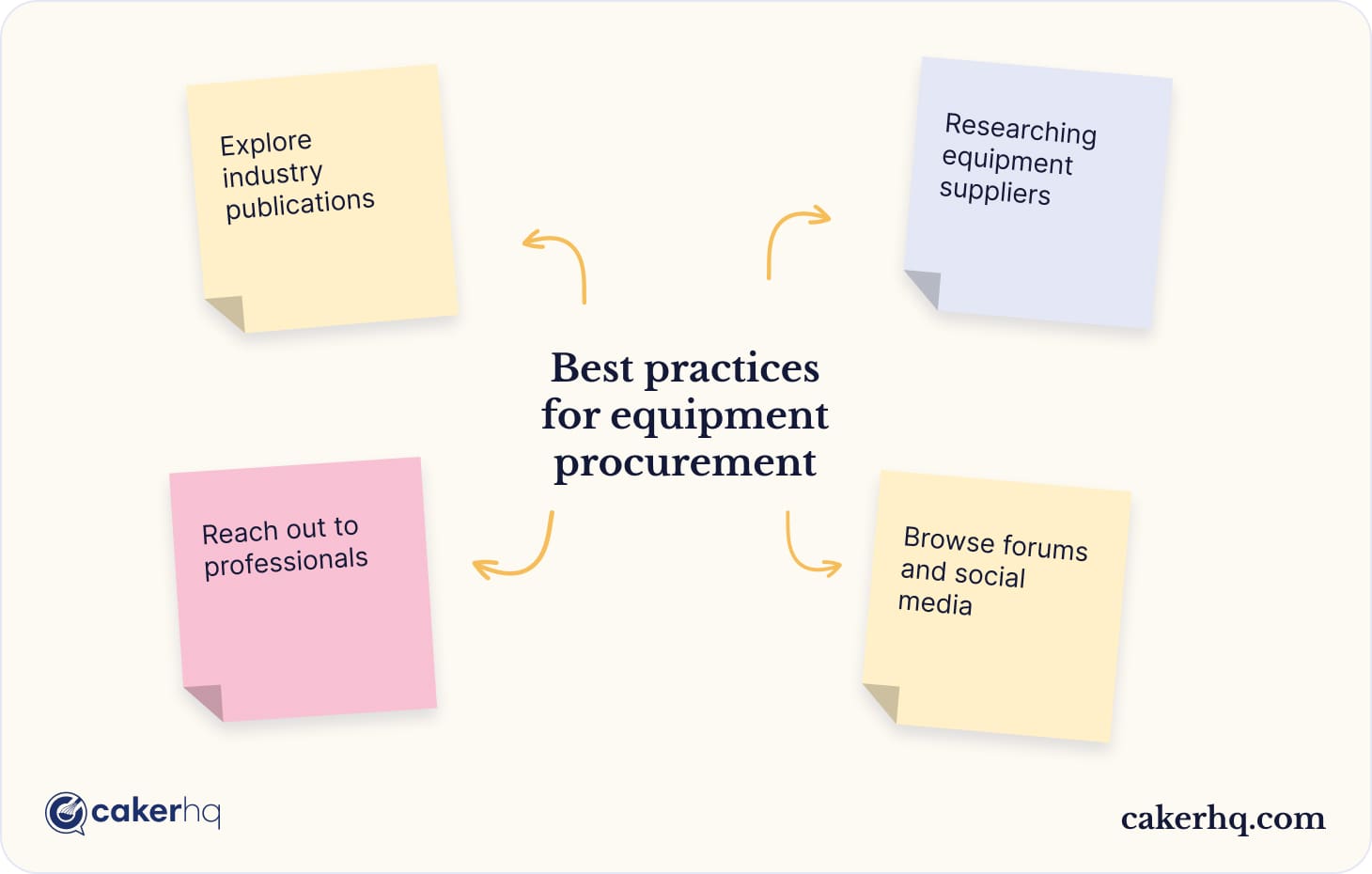

Best practices for equipment procurement

For the last stop in this extensive piece, let’s cover a few tips about your future equipment procurement. Although some may seem obvious, it still a good thing to keep them all in one place, isn’t it?

Researching equipment suppliers

Researching suppliers is an absolute must when choosing reliable equipment that lasts for years. To start, you should identify reputable and reliable suppliers in the bakery industry. You may already know some of them, but you can discover even more by browsing forums and dedicated discussions. Platforms like Reddit or Facebook are your best friends in this matter. Additionally, reach out to other bakery owners or industry professionals for recommendations and insights based on their experiences with equipment suppliers.

To go even further, you can also explore industry publications and attend trade shows to gather information about different suppliers and their product offerings. Consider things you should worry about the most:

- Reputation;

- Experience in the niche;

- Overall product quality;

- Customer service.

Assessing warranty and after-sales support

Once you’re ready to buy everything you need, keep an eye on suppliers that offer comprehensive warranty coverage and reliable after-sales support services. Make sure you review the warranty terms and conditions for each equipment purchase to understand the extent of coverage and any limitations or exclusions.

Additionally, inquire about the availability of technical support, troubleshooting assistance, and replacement parts to address any issues that may arise during equipment use.

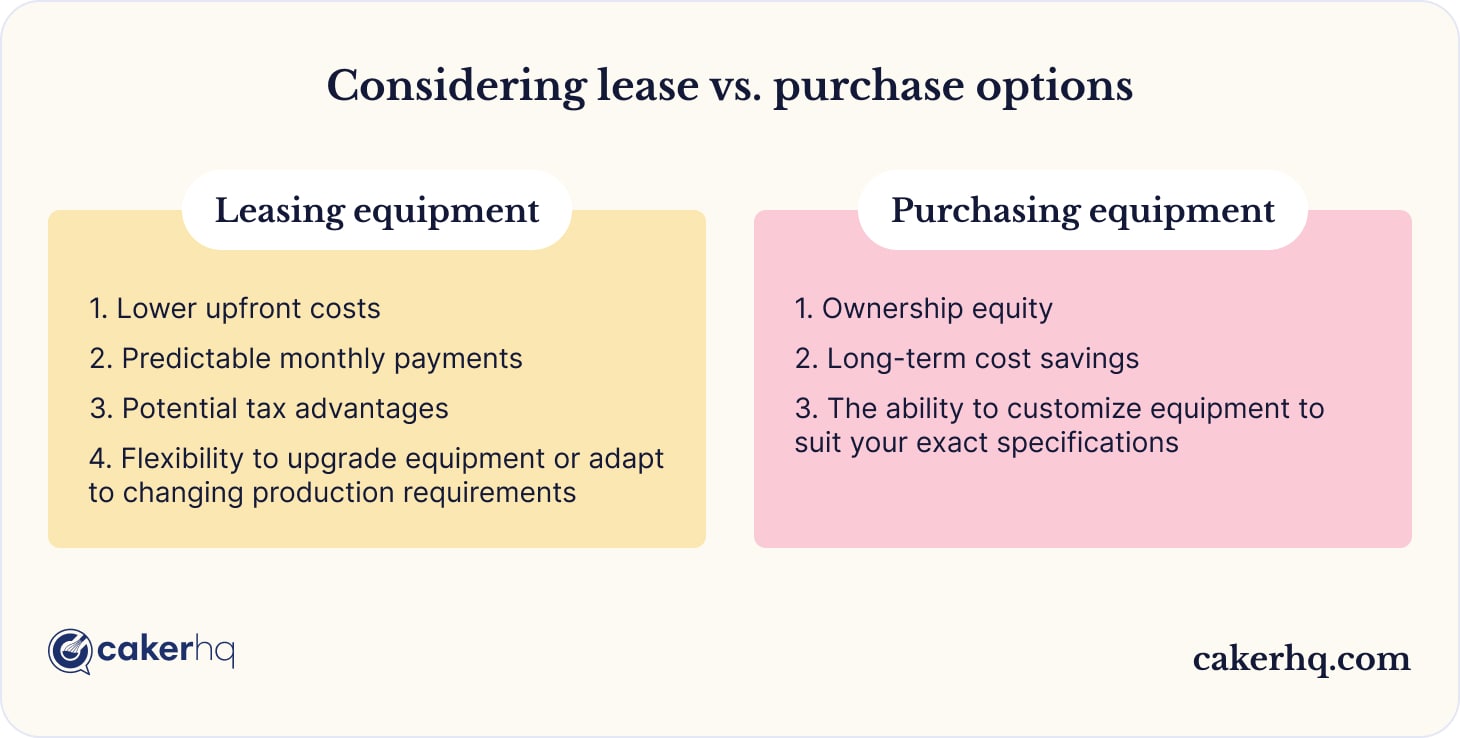

Considering lease vs. purchase options

When you calculate even approximate costs for everything you need, you may see a number that goes way over the top of your budget. Therefore, evaluate the pros and cons of leasing versus purchasing bakery equipment based on your specific business needs and financial situation.

When you think of leasing equipment, it can provide some benefits:

- Lower upfront costs;

- Predictable monthly payments;

- Potential tax advantages;

- Flexibility to upgrade equipment or adapt to changing production requirements;

On the other hand, purchasing equipment outright may offer other kinds of advantages, such as:

- Ownership equity;

- Long-term cost savings;

- The ability to customise equipment to suit your exact specifications.

After all, consider factors such as equipment lifespan, usage frequency, and financial objectives when deciding between lease and purchase options.

Bottom line

That’s a wrap for now. As you can see, choosing the best equipment for a small bakery business isn’t as easy as it seems at first glance. It requires thorough planning and a lot of hassle. Yet, in return, few things are as fascinating as entering a professionally designed and equipped bakery. Therefore, if you’re head-to-toe engaged in the process, we sincerely hope our guide will help you and you will enjoy the process.

Additionally, feel free to refer to our blog, as we regularly cover many more cake-making-related topics that may help you streamline operations and cultivate a more substantial business.